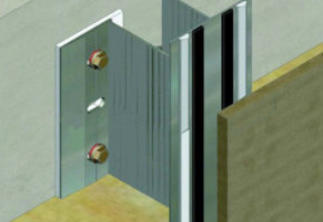

Aluminum and galvanized profiles are used in rivet system. The rivet points

of the panels and the carrier profiles are drilled 8mm in diameter (sliding

point). They are mounted to the system with rivets of 4.8mm diameter. The

head diameter of the rivets should be 14-16 mm. Certain points of the

panels are drilled to the same size (4.8mm) as the rivet diameter (fixing

point). The color of the rivets can be the same as the color of the aluminum

or the color of the panel. Screwing is the most common system for fixing

Viroc panels in terms of efficiency and ease of application. The

substructure can be metal or wood. Due to the similarity of performance of

the materials, it is more convenient to use wood substructure. In outdoor

applications, the relative humidity difference in the air and the exposure of

the panels to the sun causes a size difference in the boards. Therefore, the

use of a screw with a head greater than the diameter of the drill hole in the

plate is recommended because it allows expansion and contraction to

occur without creating any tension.Screws to be used on exterior facades

should be stainless steel.

Viroc panels with a maximum thickness of 10mm can

be fixed to a metal or wood substructure with adhesive

fixing system. The adhesive system generally consists

of an adhesive (polyurethane, MS Polymer or hybrid

paste), a double-sided adhesive tape, and a primer set

to be applied to the substructure. It is not recommended

to use the adhesive system outdoors. In countries with

special fire regulations, this system is not allowed, as

adhesives such as polyurethane, MS polymer etc. do

not have fire resistance.

© SARGRUP İNŞAAT VE ENERJİ LTD.ŞTİ. T: +90 212 418 45 35 M: +90 532 211 27 94 E:

info@sargrup.com.tr

FIXING SYSTEM WITH RIVET OR SCREW

FIXING SYSTEM WITH ADHESIVE